| Home |

| Proven Low Tech |

| Trial Build |

| DIY Sail Development |

| Oars Free Plans |

| Contacts |

| Site Map |

Designer speeding in a GIS

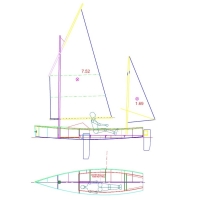

The RAID41

Racing/Cruising Dinghy

Designed for purpose

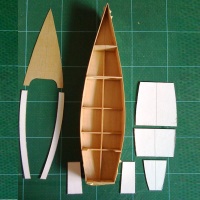

Simple Assembly

Prefabrication building method

This is the prototype build in the UK. The team has worked out a simpler method to reduce labour and timber costs. More Pics available on co-builder Chris's Photos on Flickr Cutting out and framing the prefabricated panelsLike all storerboatplans the raid 41 is designed around the "Instant" style of boatbuilding pioneered by Jack Holt and then pushed further by Phil Bolger and Dynamite Payson. The plan style is highly detailed showing how to accomplish each step.It also leverages some of the lessons I learned from the PDRacer project about simplifying while keeping the final result looking slick and polished. The plans give the layout and sizing of each panel of the boat.  These are cut out in the correct order to create a panel set. Boatbuilding pics are from Chris' Backyard.  The required parts have framing attached to take any structural joins. In the revised version the amount of framing has been substantially reduced.  Going 3D - Assembling the flat pack into a boat.Brian (the owner in the UK) takes over the explanation:For anyone following the prototype build for RAID41, I am really pleased to say we have just made real progress this last week. We now have the hull skeleton epoxy glued together, and a very exciting shape she is. Very different, very light, really pleased.  Here you can see the shape in scale. Notice the right hand chine is a poor shape without the chine log added. The hull side when first screwed to the bulkheads takes up a rather wavy shape. However clamp on a chine log and magic happens - lovely shape is taken up. (Don't overtighen the screws holding the side panel to the bulkheads before the chine log goes on - Boatmik)  Both chine logs dropped in place, lovely shape for a box boat. To check alignment, a vertical piece of wood was clamped to bulkhead 1 using a set square sitting on the bulkhead edge. A piece of wood clamp to the stem meant we could sight between the two to check alignment in the vertical plane. The stem could still have been offset, so diagonal measurements were taken from the bulkhead 1 intersection with the hull sides and checked they were the same.  After a few attempts and finally deciding we were there, on checking the side panel alignment at the stem the two panels were meeting spot on and sitting just right against the stem. Very clever man that Mr Storer. (Um, I think we can blame the computer in this case, Brian! And your and Chris' backyard efforts in boatbuilding) This next picture shows the structure glued up, centre stringer clamped in. Just after this we added the floor stringers. We could then really see the lightweight structure forming a very impressive skeletal structure.  The phrase " Low Cost - Hidden High Tech" springs into my mind. (My feeling is that it leverages the Australian lightweight wooden boatbuilding tradition using the prefab construction methods mentioned at the beginning of this page - Boatmik) More to come! |